Zice Seal, located in Songjiang Industrial Zone, Shanghai, is a manufacturing company specializing in the research, development, production, and sale of high-quality rubber sealing products. Over the years, the company has consistently prioritized quality as the core of its development. To maintain strict quality standards, Zicai Sealing has obtained certification for the IATF 16949:2016 quality management system. This has earned the trust of numerous domestic and international clients over more than two decades of growth, with products exported to countries and regions such as South Korea, Japan, Russia, Southeast Asia, and Europe and America!

Main Products: O-rings (perfluoroether, coated, extra-large sizes, precision sizes, fire-resistant, explosion-proof, conductive, food-grade), Flat gaskets, U/Y/V-shaped gaskets, Rubber strips, Rubber balls, Rubber retainers, ED-type connectors, High-pressure water seals, Lip seals, Polyurethane products, PTFE gaskets, and various special rubber components.

Our products are widely used in various industries including semiconductors, new energy, photovoltaics, automotive, hydraulics, pumps and valves, aerospace, petrochemicals, construction machinery, electronics, chemicals, high-pressure washing machines, water treatment equipment, shipping, food, healthcare, home appliances, and cosmetic containers. Tairlock Sealing has successfully collaborated with numerous domestic and international industries and manufacturers, earning the trust of its customers.

Our company has passed

Raw materials comply with PAHS, NSF, UL, WRAS, and other relevant testing requirements

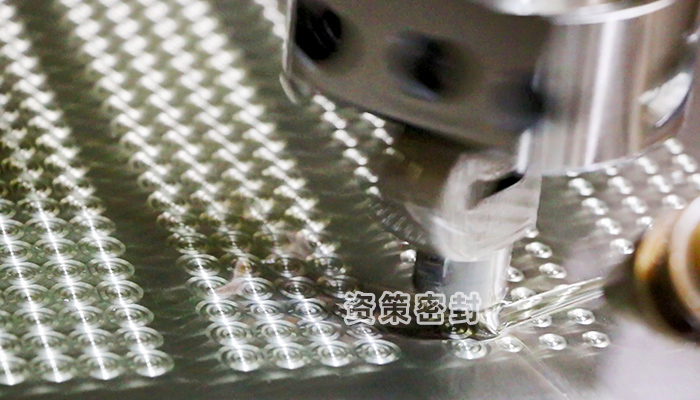

The technical team has over 20 years of experience in R&D, design, and production of rubber seals. The company has introduced high-precision CNC machining mold lathes and independently developed high-precision molds, enabling quick prototyping and production based on customer-provided drawings or samples. Standard parts are produced without mold fees.

Use high-quality imported materials, establish a strategic cooperation platform with raw material suppliers, share industry information, and quickly apply them to product development.

Materials available include: (FFKM) Perfluoroelastomer, (FKM) Fluoroelastomer, (NBR) Nitrile Butadiene Rubber, (HNBR) Hydrogenated Nitrile Butadiene Rubber, (EPDM) Ethylene Propylene Diene Monomer Rubber, (SI) Silicone Rubber, (FVMQ) Fluorosilicone Rubber, (CR) Chloroprene Rubber, (NR) Natural Rubber, (PU) Polyurethane, (PTFE) Polytetrafluoroethylene, and many others.

The product demonstrates excellent performance in corrosion resistance, wear resistance, temperature resistance, and resistance to special media. The material hardness can range from 30 to 95 degrees, while maintaining good elasticity and compression deformation rate. The product undergoes quality inspection using automatic full inspection equipment, significantly reducing defects such as flash burrs and impurities, ensuring high dimensional accuracy and strong stability. It can be supplied with wire diameters as small as 0.5mm and inner diameters as large as several meters.

Factory pictures

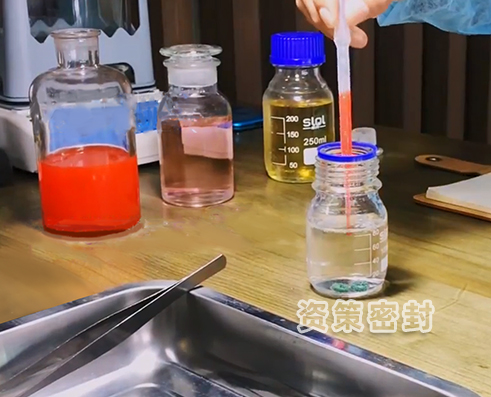

Raw Material Testing

Mould Development

Rubber Compounding

Production workshop

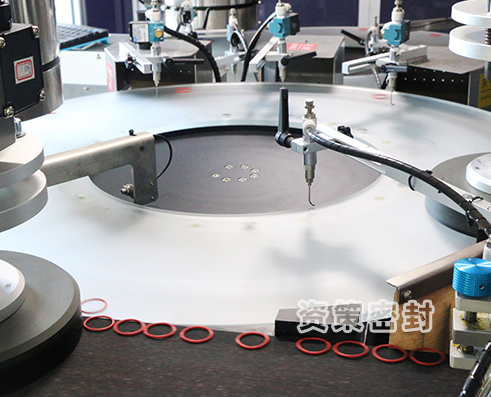

Automated Edge Removal

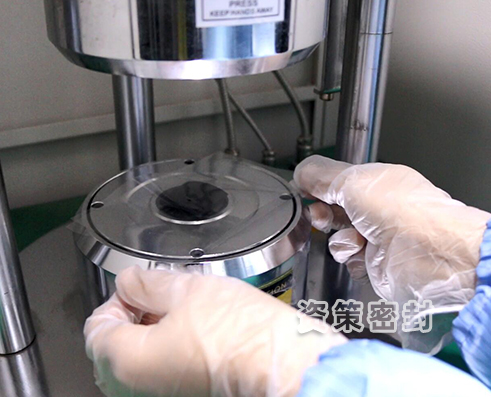

Performance Testing

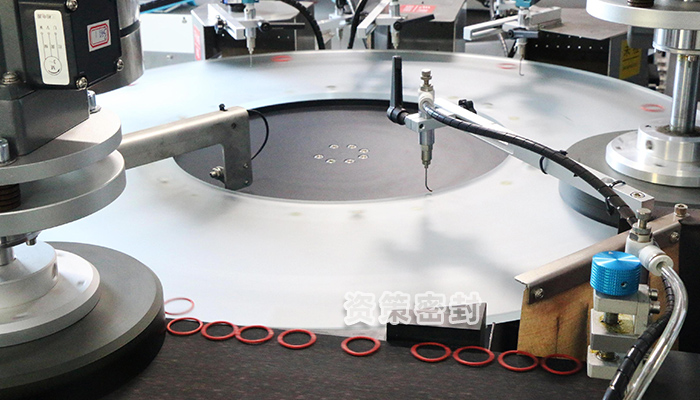

Automated Full Inspection

Automation Packaging

Copyright©Shanghai Zice Seal Technology Co.,Ltd. 沪ICP备12024584号-3